Reflow Tray for IC Chip Testing

Reflow tray for testing of IC chip through a PCB board reflow soldering machine. Test jig holding tray for IC chip testing.

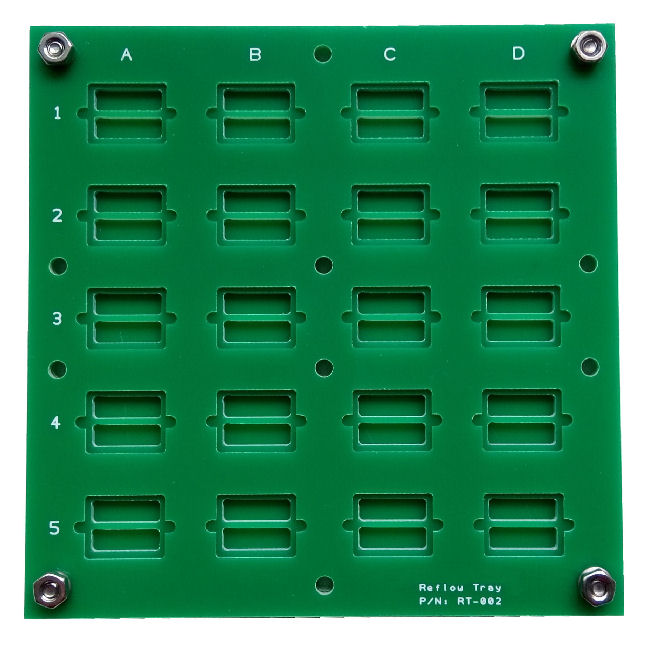

Available reflow tray design

- RT-000 (base plate to protect the bottom of the board)

- RT-001 (middle plate to support the IC chip)

- RT-002 (top plate to hold the chip in position)

PCB board milling for different layers creating a 3D test tray for holding IC chip in position.

Specification

- Board thickness 3.2mm.

- Green soldering mask on PCB board. (also available in Black color mask)

- Text printing using white silk screen.

- Designed to hold 20pcs of BGA IC chips.

- IC chip holder space tolerence ±0.2mm

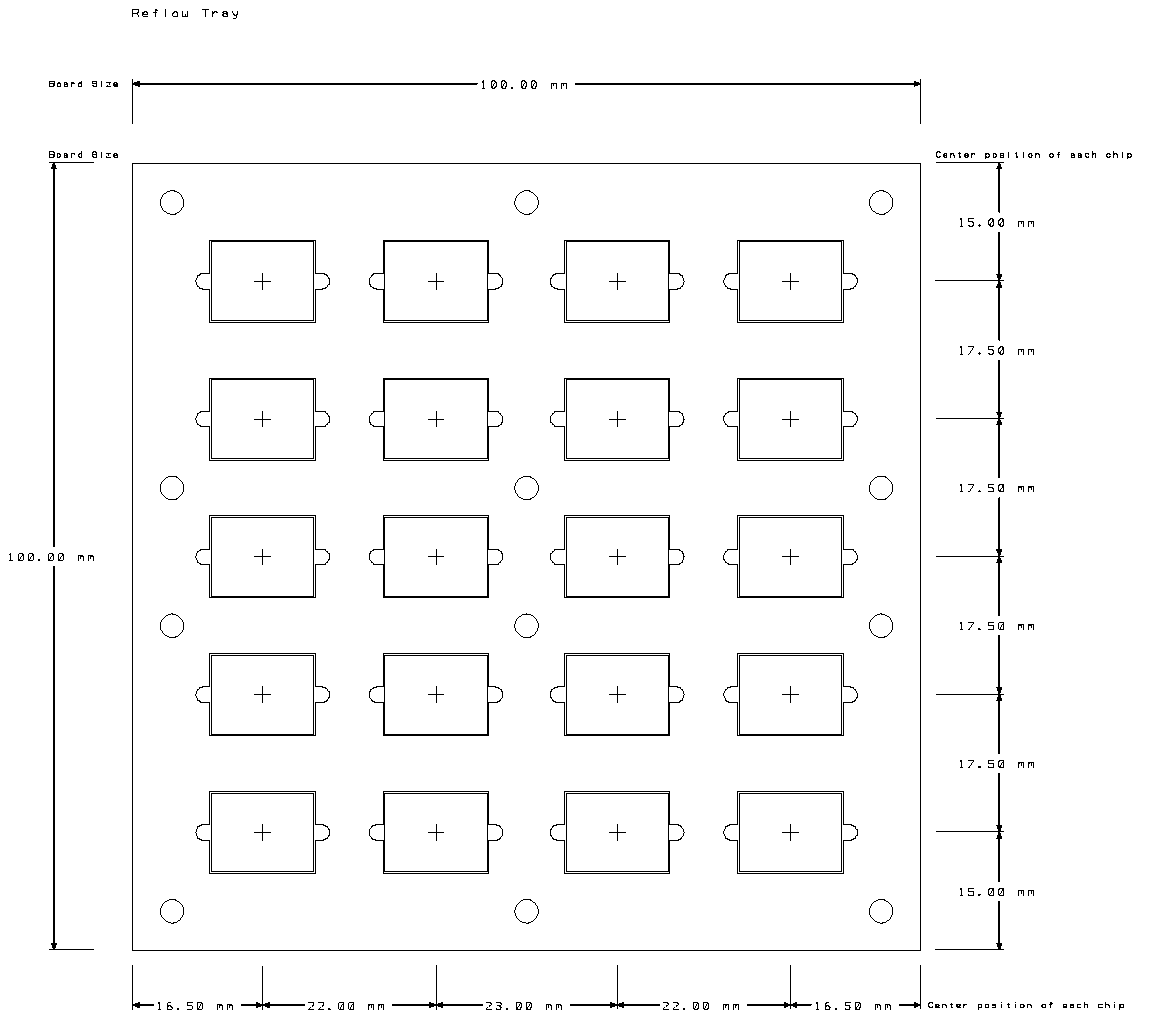

- Reflow tray size (100 x 100mm)

- 12x alignment holes (⌀3mm)

- Secure by 4x Button cap screw M3x6, a spring washer and a nut

Dimension

Use Instruction

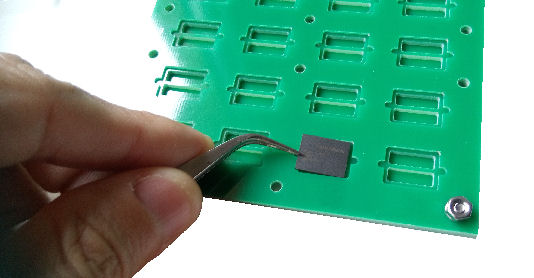

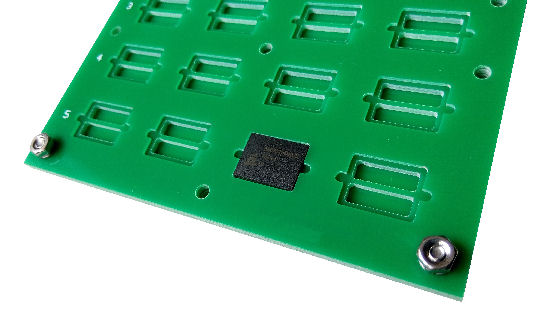

- Place the IC Chips (test subject) on the reflow tray.

- Position the tray with the IC chips on a reflow soldering oven or the reflow soldering conveyor belt.

- Reflow soldering takes about 5mins, with a temperature reaching a peak of about 250°C.

- Allows the tray to be cool, and pick up from the reflow machinery.

- Allow the tray to cool down before using it for the next round of reflow testing.

The PCB will turn dark green under normal usage after using it for a number of times.

Warning: If the tray is being over heated, the green mask can start to be decolourised. Burned mark with brown black color can be observed.

Typical Reflow Soldering Profile

- Preheat (to 150°C in 60 sec)

- Soak (from 150°C to 165°C in 120 sec)

- Reflow (reaching peak temperature of 225°C to 235°C, holding it for about 20 sec)

- Cooling (-4°C/s or free-air cooling)