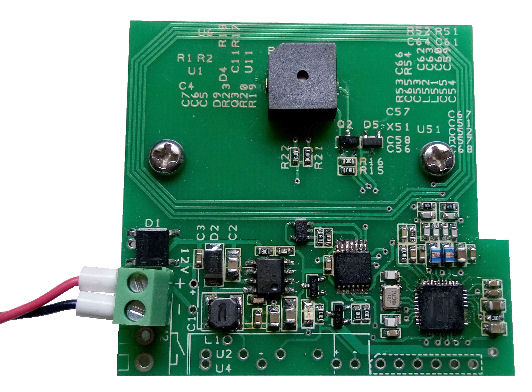

Leasing of electronic design and hardware is a form of renting the devices/equipment instead of owning them.

Instead of investing in the project electronic hardware design and owning the hardware, you can consider a leasing business model. You will be able to predict your monthly expense as well as having the technical support to maintain the electronic hardware deployed.

Suitable for,

- Project operating in a lease or rental modal.

- Businesses who want a guaranteed cost cap (limit).

- Businesses who do not have their own technical team/staffs.

- Long-term deployment on site.

How does it work?

You have a project that needs a new electronic hardware installation. The development, production and maintenance cost can be extremely difficult to determine.

Approach PIC-CONTROL with your project proposal. We can propose you with a leasing model. You can then lease and pay as you use. You manage the project, while we take care of the technical implementation.

Advantages

- Predictable expense. (Yearly billing in January)

- Lower initial investment, or pay nothing upfront.

- Warranty and technical support during the lease period.

- Less risk when deploying a new design project (design or idea that is not yet tested).

- Continuous design and hardware update and improvement.

- No replacement cost of damage electronic hardware.

- Design and production will be taken care of.

Disadvantages

- Do not own the design rights of the electronic hardware.

- Design and production lead time may be slightly longer.

- Cost is slightly more compare to paying outright to own the electronic hardware over a longer term.

- Do not have full control over how the hardware is to be deployed.

Project Eligible for Leasing

The criteria in accepting your project for leasing is subjected to a review and approval from PIC-CONTROL.

Due to a possible complication, project application has to be fully disclosed. PIC-CONTROL can only undertake a lease rental model with sufficient information.

The following is some guideline for accepting a project for leasing,

- Project detail needs to be presented for an assessment.

- Practical technical implementation.

- The trend of your project application is fairly predictable.

- Common application.

- Design can easily be reused.

- Potential of deploying more and growing trend.

- The client must have a good credit record.

- Is not NDA (non-disclosure agreement) in nature.

- Close collaboration.

Please note that a detailed understanding of your project is required. Meeting without prior assessment of project information is subjected to consultation charges. Please email us your project detail first.

Contact PIC-CONTROL for further information.