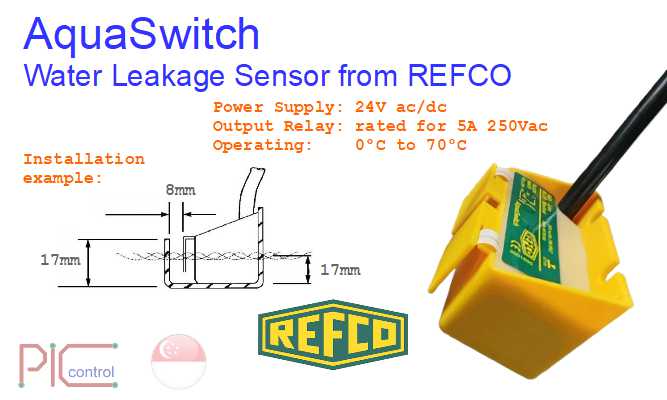

The REFCO AquaSwitch Aircon Water Leakage Sensor is a specialized electronic device designed to detect water levels in air conditioning units, thereby preventing potential water damage due to leaks (or aircon condensation).

This sensor is particularly useful in environments where air conditioning systems are prevalent, such as commercial buildings and server rooms, where water leakage can lead to significant operational disruptions and costly repairs.

Overview of AquaSwitch

The AquaSwitch operates using solid-state electronic sensing technology, which is not affected by oil films or metal surfaces. This feature enhances its reliability in various installation scenarios. When water comes into contact with the sensor, it triggers a relay output that can activate alarms or pumps, ensuring immediate response to potential leaks.

Key Features

- No Moving Parts: The AquaSwitch is designed without mechanical components, reducing the risk of wear and tear and increasing longevity.

- Relay Output: It provides a dry contact switch output that can be easily integrated into existing alarm systems or control panels.

- Versatile Installation: The sensor can be mounted in various locations, such as in the water tray of an air conditioning unit or at specific heights to monitor water levels effectively.

- User-Friendly: The installation process is straightforward, making it accessible for both professional technicians and DIY enthusiasts.

Applications

The AquaSwitch is particularly effective in:

- Air Conditioning Units: It helps monitor condensation trays where water accumulation is common.

- Server Rooms: Given that air conditioning failures can lead to overheating and equipment damage, the AquaSwitch provides critical early warnings of leaks2.

- Industrial Settings: In environments with extensive piping and machinery, the sensor aids in maintaining operational integrity by detecting leaks before they escalate into larger issues.

Advantages

The AquaSwitch offers several benefits:

- Early Detection: By alerting users to leaks promptly, it helps mitigate damage and repair costs.

- Peace of Mind: Users can operate their systems with confidence, knowing that potential water issues are being monitored continuously.

- Cost-Effective Solution: The initial investment in an AquaSwitch can save significant amounts in potential repair costs due to water damage.

The REFCO AquaSwitch Aircon Water Leakage Sensor is a reliable and efficient solution for detecting water leaks in air conditioning systems. Its advanced technology and user-friendly design make it an essential tool for maintaining the integrity of HVAC systems across various applications.

Buy AquaSwitch here.

SGD$ 295

Click on this buy button to purchase.

24V ac/dc model.

or Contact our sales for ordering of AquaSwitch water leakage sensor.

For more technical details of the AquaSwitch sensor, click here.